| [Index] |

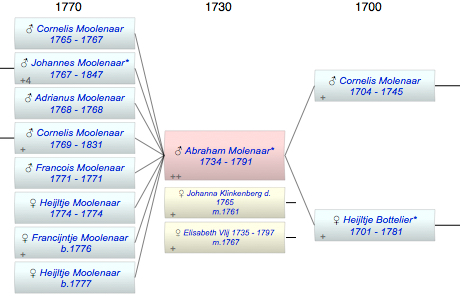

| Abraham Molenaar* (1734 - 1791) |

|

| b. 14 Mar 1734 at Haarlem, NL |

| m. (1) 31 May 1761 Johanna Klinkenberg ( - 1765) at Haarlem, NL |

| m. (2) 25 Jan 1767 Elisabeth Vlij (1735 - 1797) at Haarlem, NL |

| d. 25 Jul 1791 at Haarlem, NL aged 57 |

| Parents: |

| Cornelis Molenaar (1704 - 1745) |

| Heijltje Aeltje Bottelier* (1701 - 1781) |

| Siblings (5): |

| Moolenaar |

| Adreiaen Melenaar (1726 - 1729) |

| Abram Molenaar (1728 - 1728) |

| Antje Melenaar (1731 - 1733) |

| Johanna Molenaar Moolenaar (1740 - 1789) |

| Events in Abraham Molenaar* (1734 - 1791)'s life | ||||

| Date | Age | Event | Place | Src |

| 14 Mar 1734 | Abraham Molenaar* was born | Haarlem, NL | ||

| 05 Jun 1745 | 11 | Death of father Cornelis Molenaar (aged 41) | buried at sea | |

| 31 May 1761 | 27 | Married Johanna Klinkenberg | Haarlem, NL | |

| 07 Jan 1765 | 30 | Birth of son Cornelis Moolenaar | Spaarndam | |

| 09 Aug 1765 | 31 | Death of wife Johanna Klinkenberg | Spaarndam | |

| 25 Jan 1767 | 32 | Married Elisabeth Vlij (aged 31) | Haarlem, NL | |

| 22 Aug 1767 | 33 | Death of son Cornelis Moolenaar (aged 2) | Haarlem, NL | |

| 27 Oct 1767 | 33 | Birth of son Johannes Molenaar Moolenaar* | Spaarndam | |

| 24 Sep 1768 | 34 | Birth of son Adrianus Moolenaar | Haarlem, NL | |

| 30 Dec 1768 | 34 | Death of son Adrianus Moolenaar | Haarlem, NL | |

| 10 Dec 1769 | 35 | Birth of son Cornelis Moolenaar | Haarlem, NL | |

| 01 Feb 1771 | 36 | Birth of son Francois Moolenaar | Haarlem, NL | |

| 29 Mar 1771 | 37 | Death of son Francois Moolenaar | Haarlem, NL | |

| 23 Feb 1774 | 39 | Birth of daughter Heijltje Moolenaar | Haarlem, NL | |

| 04 Mar 1774 | 39 | Death of daughter Heijltje Moolenaar | Haarlem, NL | |

| 12 Jun 1776 | 42 | Birth of daughter Francijntje Moolenaar | Haarlem, NL | |

| 30 Dec 1777 | 43 | Birth of daughter Heijltje Moolenaar | Haarlem, NL | |

| 26 May 1781 | 47 | Death of mother Heijltje Aeltje Bottelier* (aged 80) | Haarlem, NL | |

| 25 Jul 1791 | 57 | Abraham Molenaar* died | Haarlem, NL | |

| Personal Notes: |

|

Many years ago there were many large lakes in Holland formed in depressions in the land. The surrounding high ground was increased whereby dikes were formed. Next wind powered watermills were installed who commenced emptying the lakes which when dry were called polders. De Beemster was one of such polders. These mills were used to maintain suitable water levels in the polder. It wasn’t until 1675 that the ARCHIMEDES or “ lift screw “ system was discovered that series of mills could be cut by almost a third to this new system’s ability for lifts of up to 5 metres, so even in those days amalgamations and loss of job opportunities were part of life. Much later steam and later electrically powered pumping stations took over their role.

Before the emptying of “ de Beemster “ a total of 49 mills were built each fitted with a paddlewheel designed and developed by the engineer called “ Leeghwater “ ( literally meaning “emptying water”). Because the supply capacity of these paddlewheels was limited to a draw of 1.3 metres it was necessary to build an additional 2 or 3 mills at different levels ( in steps ) in the lower portions of the polder. These were then called “ a chain of mills “ each supplying water to the next higher positioned mill. The 3rd mill would be called the lower mill, the second the middle mill and the 1st the upper mill. According to a map of 1611 there existed on the eastern ring canal of ‘ de Beemster’ near the Quadijker bridge ( it is now spelled Kwadijk ) 2 mills; however a map from 1612/1613 showed already a 3 mill chain consisting of an upper, middle and lower mill which was supplied with water via a long supply canal which crossed both road channels alongside the road to Purmerend and alongside the Rijper road and which continued to the eastern canal where later the new lower mill No.4 was built. These mills have operated for some 270 years to ensure the correct water levels in the Beemsterpolder. The end of their demise commenced in July 1884 when mill no.4 was hit by lightning and burnt to the ground. A year later, also in July, lightning hit one of the remaining 3 mills. The newspaper report did not mention which particular mill was involved, only that the resulting fire was successfully contained by the miller. Two years later on the 24th of June 1886 the chain of the 3 mills together with 4 mills of another chain were offered up for sale for demolishing. The mills of the Quadijker chain were sold for respectively 440, 375 and 480 guilders. Perhaps from these figures the assumption can be made that it was the middle ( no.2 ) mill that was hit by lightning and where Cornelis Teunisz carried out his trade as miller ( molenaer ) and thereby established the origin of our family name. The task of the Miller: That life was tough in those days is well known. Labour from early morning till late at night was the norm and did not leave much room for recreation. Mostly people retired soon after the evening meal to ensure a good night’s rest. The miller however could not even be assured of that because all sorts of situations could force him to react immediately. He was duty bound as long as the required water levels were not reached to pump day and night, seven days a week ( providing there was sufficient wind ). He was not allowed to : a/ pass on his duties to a relief and b/ leave his ( working ) mill for whatever reason and was expected to be attentive to any unexpected event. In the case of the mills on the eastern ring canal of the Beemster especially, a lot of work could be expected by upcoming and increasing westerly winds which pushed water in ditches and canals in an easterly direction. The miller then had to ensure that his windvanes were turned into the wind. In the North Holland type mill this occurred internally where the complete millcap including the vanes were turned manually. In polder mills elsewhere this occurred externally as they were fitted with a tail and the vanes were turned by means of a turnwheel. He also had his hands full ensuring the correct amount of sail was fitted to the vanes. More sail when the wind dropped, less sail when the wind increased. This of course was carried out at night as well and in all sorts of weather conditions and the only available light in those days was the old oil lantern. However even if everything was finally working satisfactorily the signal to “ stop pumping immediately “ could come because the amount of water displaced by the lower mill was greater than could be handled by the mills whose task it was to pump that water into larger bodies of canals, rivers or sea particularly so in times of floods or high tides. The miller obtained those signals ( and passed these on to the next mill ) by means of a blue flag during daylight hours or a lantern at night. During heavy rainfalls or fog these systems were hardly visible and therefore required such a high degree of vigilance that the poor miller did not even have time for a short nap. ADDENDUM. During non-working periods the vanes were also used to pass messages to neighboring mills by positioning the vanes in certain ways in pre-arranged codes to announce sickness, births, festivities or deaths. This information was supplied by Erik Moolenaar of Voorschoten. He also supplied the following information on Cornelis Molenaar who was baptized in Haarlem in 1704. |

| Created on 30 Dec 2018 |